The Role of CNC Machining in Smart Wearable Prototypes

To stay ahead of your competitors, you need innovation and cutting-edge technology. Therefore, manufacturers look for methods to increase their production scale while offering better functionality. Wearable technology is an important factor that evolves everyday electronics and their performance. Although wearable prototypes are small in size, they are complex in design, and their demand is paramount. However, when it comes to the manufacturing industry, where precision and customization are necessary, you need a special method to produce wearable parts.

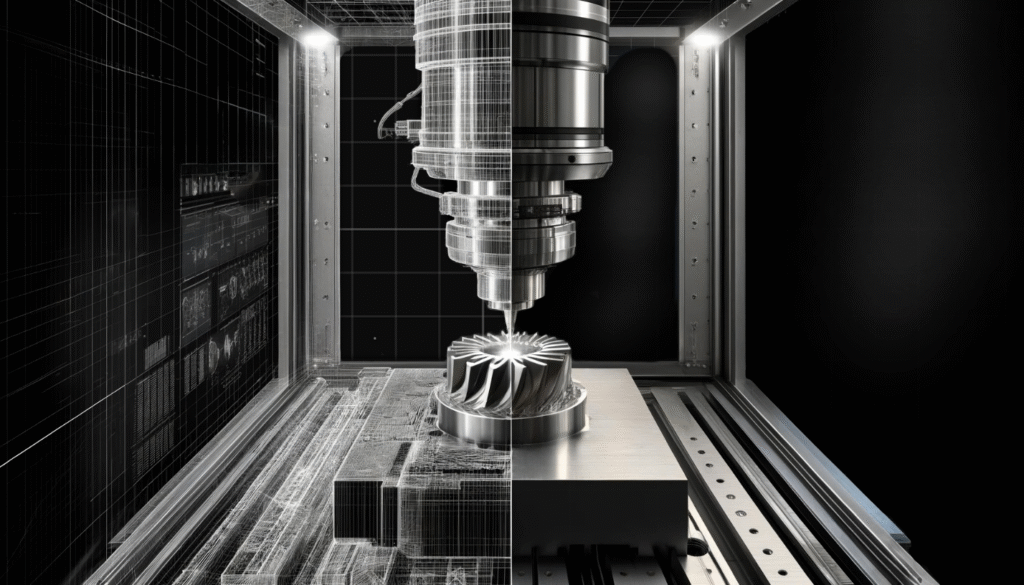

CNC machining is a pivotal method that revolutionizes the manufacturing industry. Although CNC is notable for aerospace and automotive, its role in the production of wearable prototypes is significant. With the multi-axis working capability, CNC machines exceed the precision demands. However, manufacturers need technological prowess and an understanding of the type and functionality of wearable prototypes.

Besides, the CNC method requires experience from the designer of the 3D model and the developer of G-code to ensure consistent quality. These machines offer precise curves and demand strict standards of quality. Let’s see the role of CNC machining in smart wearable prototypes in more detail.

CNC Machining and Its Role in Wearable Prototyping

Wearable machinery has an important role in modern-day facilities in terms of connectivity and productivity. From smart devices to digital sensors, they offer comfort and make our lives easier with high-end precision. The CNC machining process uses a programming language to control the tools and offer precise results. Drilling, milling, and carving, everything result in accurate results. Therefore, for smart wearable prototyping, CNC is the ideal method to manufacture parts with precise designs.

Manufacturers need to analyze every millimeter and make sure the parts work well together, offering minimal error. Besides, wearable devices often need parts made of different materials, from plastics to metals. CNC machines handle the diverse parts with a variety of materials easily without compromising quality and precision.

Prototyping Smart Wearables with Precision CNC Machining

Wearable smart devices such as watches and monitors need durable and precise functional parts. The manufacturing of small, light, and quality parts for wearable devices is not a simple task. Consequently, precision engineering is needed to produce these parts accurately at the micro level. CNC Precision Machining can create parts with extreme customization and complicated designs. Moreover, during the prototyping, the engineers can enhance the aesthetics and product quality. Here are some major benefits that make the role of CNC machining in smart wearable prototyping more significant:

Personalization

In the modern era, people need products that not only offer functionality but also aesthetics. So, to create such parts, there needs to be special minimal parts that surpass the standard precision needed and aesthetic appeal. The smaller the parts are, the better a wearable smart device’s appearance can be. Whether users need fitness trackers with a special fit or a unique design, CNC manufacturing can offer it all.

Innovation and Speed

CNC machining is an ideal choice for manufacturing new designs. No matter what type of complex part the smart wearable prototyping needs, CNC machining can offer that. The designers and engineers create a 3D model and try different shapes and sizes according to the needs. Moreover, the CNC machining process is fast and iterative and can support any scale of production.

Streamlining of Prototyping

Another major benefit of CNC machining is that it can streamline the development process of smart wearable devices. Traditional manufacturing methods need the expertise of the workforce. Thus, they can’t guarantee precision. The cutting and procedures done by hand often come with inconsistencies and errors. However, CNC machining includes computer-aided, which offers precise results.

In addition, micro-machining is the key to miniature devices. Smart rings and earbuds, and patches continue to become progressively smaller in size. The size of these housings stretches only to a few millimeters. So, inaccuracies caused by tool wobble, surface errors lead to failures. Thanks to 5-axis systems. These provide users with a unique capability. The machine helps provide well-defined, tight channels and internal pockets. The method protects the exact position of each sensor device.

Durability

Smart devices must withstand wear and tear while offering comfort. CNC machining offers durability and can work with different materials such as plastics, aluminum, titanium, steel, and others. Aluminum feels premium and finishes well. Titanium resists sweat, impact, and sterilization cycles. In addition, Titanium is the most popular choice for the production of smart, lightweight wearable devices. The reason is its corrosion resistance, strength, and lightweight. CNC lets you test both quickly, and on top, you do not need an expensive mold. Manufacturers usually try different materials to use the most suitable one for the final product. Besides metals, plastics like PEEK, Delrin, or PC can also be machined, and these options are ideal for fitness bands and smart patches.

Finishing Quality

Modern era people look for aesthetics combined with functionality, so a surface finish is a must. CNC machining offers different surface finishing treatments, such as polishing, anodizing, and grinding. The post-processing treatments and finishes enhance the functionality and aesthetics of products. For example, anodizing can improve the hardness of aluminum parts and offer better resistance to wear and tear.

Cost Efficiency and Scalability

CNC machining for smart wearable prototyping might seem expensive, but it’s cost-efficient. Whether it’s a small-scale or large production, CNC offers precise results that lead to less material and time wastage. Moreover, it includes less labor and offers better quality control. Besides, for the tech industry, scalability matters. CNC can offer better quality and production scale control after the finalization of the design. Thus, wearable tech companies can have requisite parts without compromising on quality.

Sustainability and Future of CNC Machining for Wearable Technology

The wearable tech industry is growing rapidly, and so does its impact on the environment. CNC offers sustainable part manufacturing by minimizing waste and ensuring better use of parts. Thus, it reduces the carbon footprint. Besides, CNC machining often uses recyclable materials, including steel, aluminum, and plastics.

AI is revolutionizing the tech world, and so it will impact CNC manufacturing. AI can analyze the design and geometry of parts closely according to requirements. Besides, AI can ensure efficiency with smarter designs that meet aesthetic and functional needs. Other than that, AR and VR technologies can transform the visualization of 3D models for CNC machining.

CNC machining is transforming the development of smart wearable prototypes. The quality, precision, and scalability meet the needs of fast technological productions. With varied materials and post-processing treatments, CNC machining ensures the aesthetics and durability of wearable devices. With the use of futuristic technology, we can expect better precision and speed to satisfy modern manufacturing prototype requirements.